August 13, 2015

NMA’s Hal Quinn: “Murkowski’s energy bill should ease way for U.S. mining”

NMA President and CEO, Hal Quinn, praises Sen. Lisa Murkowski&#...

Read More ›

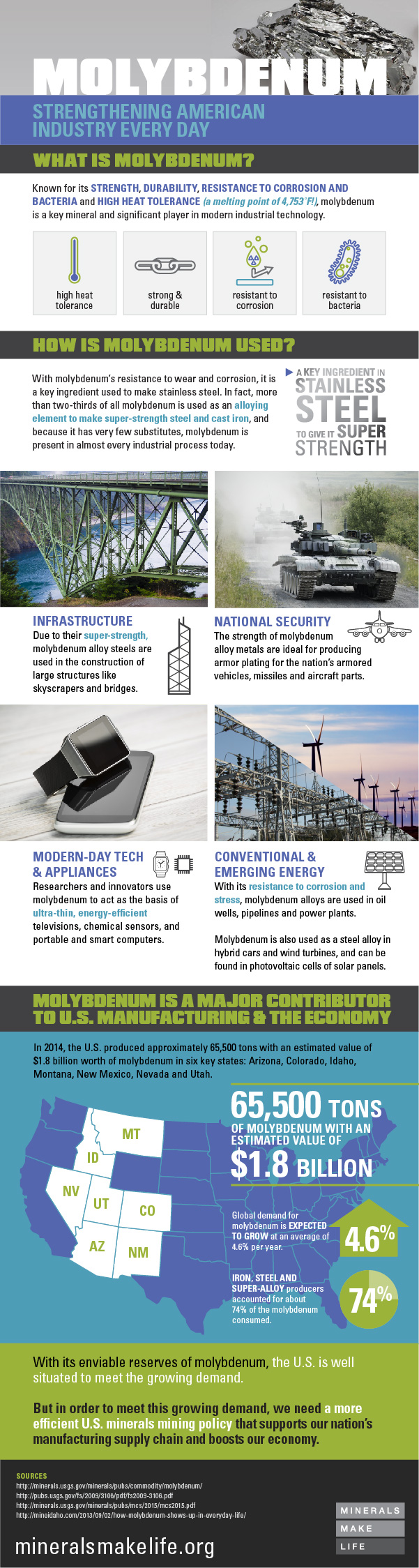

From the construction of the world’s longest bridges and tallest skyscrapers to the ultra-thin design of today’s high-tech electronics, molybdenum is one of the irreplaceable elements central to the strength and durability of America’s industries.

As depicted in the infographic below, molybdenum’s distinct properties of strength, durability, resistance to corrosion and high heat tolerance make it an extremely tough metal and the element of choice in today’s industrial processes. In fact, one-third of all molybdenum is used as an alloying agent to make the super-strength steel and cast iron that are critical to the world’s building and transportation infrastructures. Because there is little substitution for molybdenum, it is present in almost every major industrial process, including the manufacturing of conventional and emerging energy technologies.

Additionally, molybdenum is a major contributor to our manufacturing sector and the U.S. economy. In 2014, the U.S. produced more than 65,000 tons of molybdenum, valued at approximately $1.8 million. As more of the world becomes developed, global demand for molybdenum is expected to grow, bringing jobs and economic growth to the U.S.

To meet the increasing demand for molybdenum and continue to strengthen American industry, a more efficient mine permitting policy is needed. The U.S. has an abundant wealth of molybdenum reserves, and in order for the country to boost domestic manufacturing and remain a global industry leader, Congress must reform the U.S.’ mine permitting process, so manufacturers can quickly access the vital minerals they need, like molybdenum.

For more information on the role minerals play in our everyday lives, see our toolkit here.